Anatomy of ZERAMEX XT

Reversible screw-retained and 100% metal-free: The Zeramex XT boasts maximum prosthetic flexibility, thanks to an unlimited range and digital workflow.

100% cement-free and metal-free: The ZERAMEX XT is the leading two-piece Zirconia, BioCeramic dental implant solution in the world.

Get to Know ZERAMEX XT

PROSTHETIC FLEXIBILITY

A high degree of flexibility thanks to straight, angled and fully customizable abutments, with platform switch capability to prevent crestal bone loss or to increase soft-tissue volume.

"BOLT-IN-TUBE"

Prevents traction from being exerted on the ceramic. Forces are absorbed by the Vicarbo screw, which functions as a bolt. The ceramic absorbs compressive forces, while the vicarbo screw counteracts tensile forces.

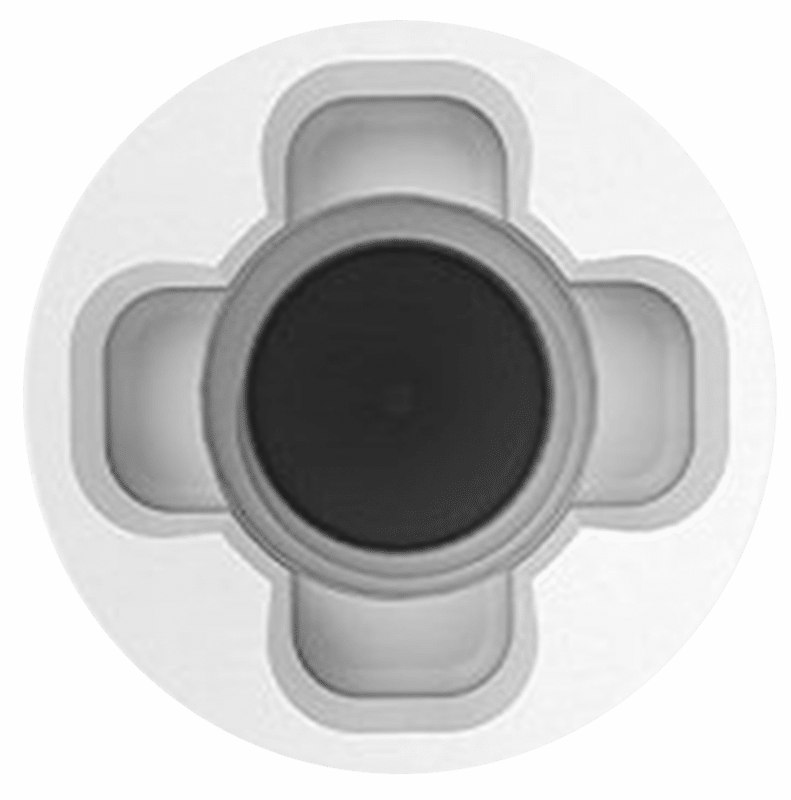

INTERNAL CONNECTION

Provides the ideal torque on insertion so that the implant can be screwed in without stress peaks being exerted on the bone. The slightly beveled contact surfaces of the implant on four prongs were developed to facilitate easy centering and placement of the abutment and auxiliary parts. The cross-shaped retaining elements are suggested to be positioned facing facial, lingual, mesial, distal.

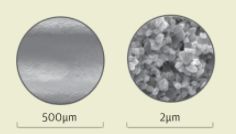

ZERAFIL™ SURFACE

Outstanding osseointegration with the hydrophilic, sandblasted and acid-etched ZERAFIL TM surface. The entire body of the implant is roughened up to the most coronal .6mm of collar height for superior soft.

SCREW HEAD ø2,8 mm

FOUR INTERLOCKS

Precise anti-rotation protection. These four retaining elements help the abutment to be securely and quickly placed in the implant. The bolt-in tube connection prevents forces being transmitted via the interlocks.

Metal Free & Cement Free VICARBO®️ CARBON-FIBER SCREW

The heart of the system and connection, a bonded, and high-performance carbon-fiber system. When tightened, the carbon-fiber screw grips the existing contour of the internal screw thread to optimally capture occlusal forces and seal the implant and abutment connection. The implant thread design and tapered cylindrical-conical implant shape achieve uniquely high primary stability for ceramic implants.

VARIABLE PLACEMENT DEPTH

The ZERAMEX® XT implant can be placed close to bone 0.6mm or 1.6mm supracrestal.

HIGH PRIMARY STABILITY

The implant thread design and tapered cylindrical-conical implant shape achieve high primary stability. The reservoir for bone grafts at the apex simplifies the placement of the implant.

ZIRCONIUM DIOXIDE ATZ-HIP BIO-CERAMIC MATERIAL

A patented manufacturing process allows for the use of hard and hot-isostatic post-sintered Zirconium dioxide. No thermal process or finishing takes place after final shaping, which ensures a high degree of precision. Innovative material for high strength and biocompatibility, it is the most complex manufacturing process of Zirconium Dioxide implants on the market.