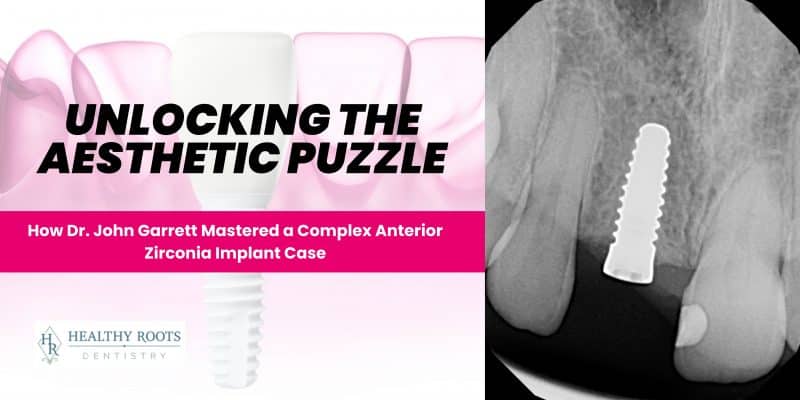

Unlocking the Aesthetic Puzzle: How Dr. John Garrett Mastered a Complex Anterior Zirconia Implant Case

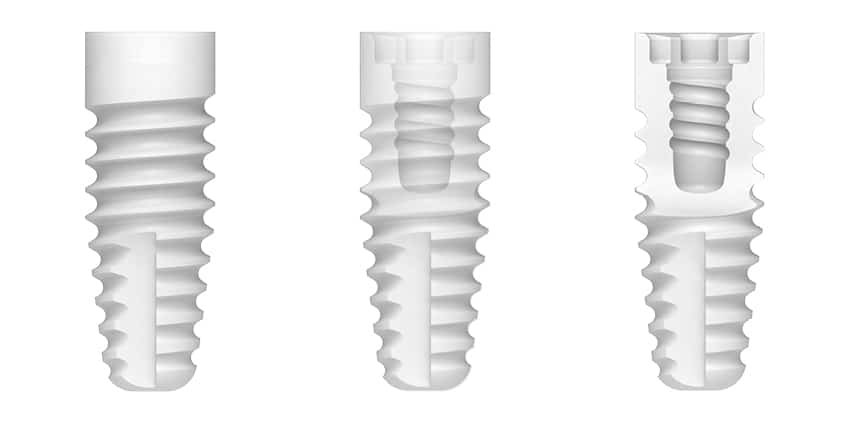

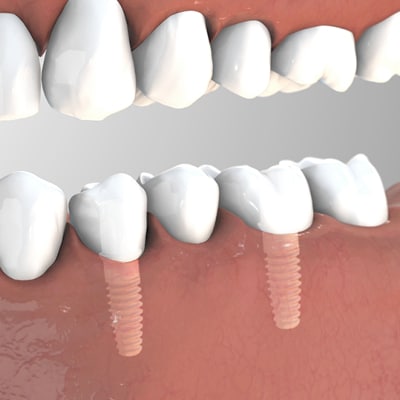

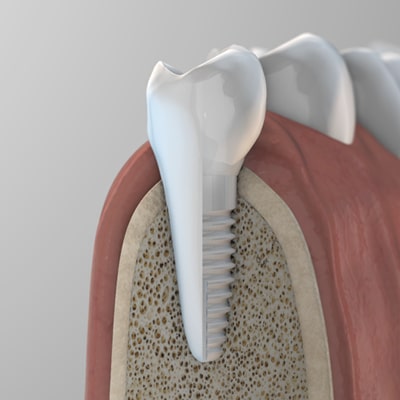

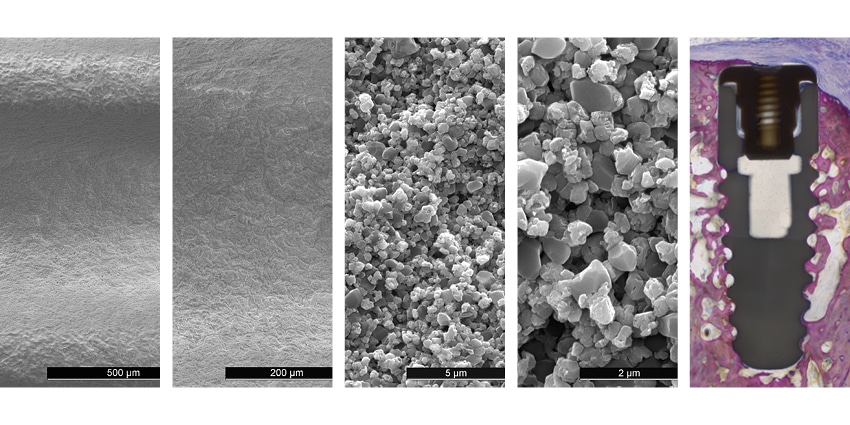

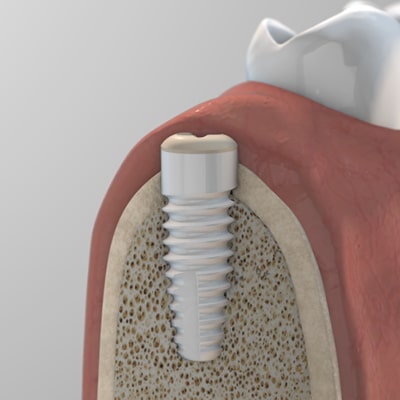

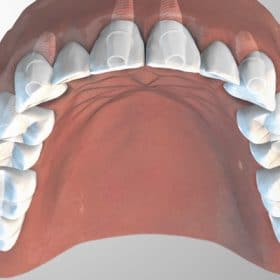

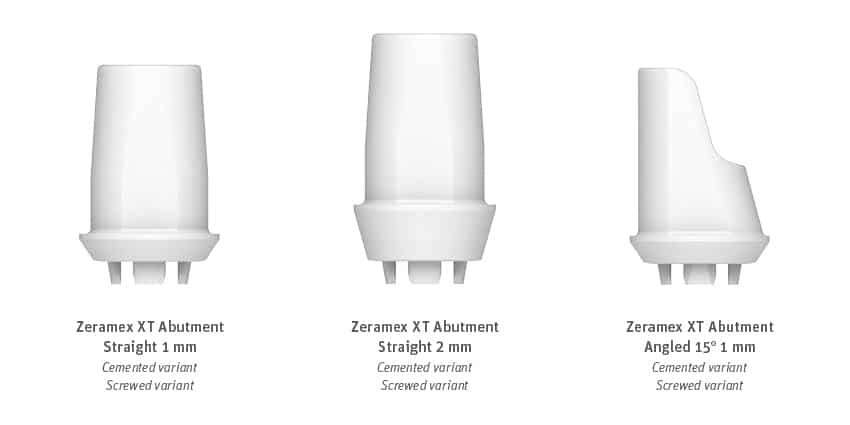

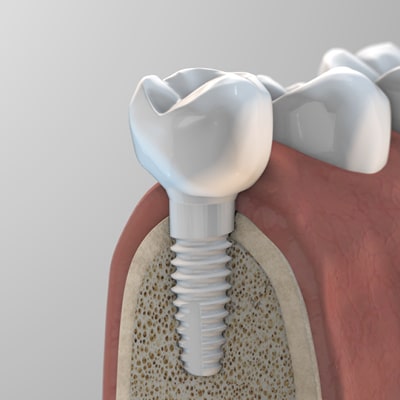

In this compelling case study, Dr. John Garrett navigates a complex aesthetic challenge to successfully place an anterior Zeramex zirconia implant. Discover how innovation and the unique properties of zirconia combined to offer a groundbreaking solution.