CAD/CAM Lab.

GUIDED SURGERY

Surgical Guide Protocols & Workflows

- Overview

- Surgical Guides

- Guide Planning Software

- Guide Surgery Kit

Step 1

Scan Patient

Step 2

Scan Model

Step 3

Plan Surgery

Step 4

Print Guide

Step 5

Place Implant

All Surgical Guides are produced using advanced digital manufacturing technologies. The surgical guides are generated by the Guide planning Software based upon the clinician’s virtual planning of the optimal location of the dental implants in the patient’s jaw bone. The software uses the dentist’s approved treatment plan to design and produce a customized surgical guide that simplifies the drilling process and guides the dentist to place the implant in the precise location as planned.

Once designed, the guides are produced automatically without any intervention by the technician, on our state-of-the-art 3D printer. They are manufactured out of a photopolymer resin approved for biomedical applications and the titanium drill sleeves are manually inserted before the guide is shipped to the doctor non-sterile.

Surgical Guide Elements improve the accuracy and safety of implant placement so that the implants can be placed correctly for the best possible aesthetics and surgical outcome. As illustrated in the images, a sugical guide has the following basic elements:

- an adaption surface, that fits onto the patient's anatomy

- drilling holes with sleeves inserted, which comply with the treatment plan and guide the actual drills; and

- optional form features like irrigation windows and holes for anchor screws and anchor pins

The Scan Implant Guide Planning Software is the software solution for dental implant treatment planning. We use the latest image processing technology and software development tools to provide dental professionals an integrated advanced image-guided dental implant treatment plan.

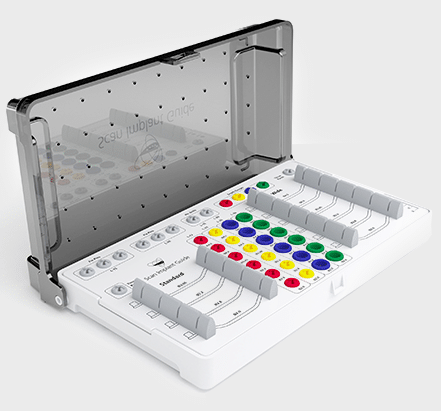

Guide’s surgical kit is designed and organized to make each instrument easily identifiable and placed within the easy reach of the clinician. The precision engineered handled drill guides are provided in a Standard Format for placing implants up to Ø4.2mm, and a Wide Format for placing implants up to Ø5.0mm. The 24 drill bits are in lengths of 17mm, 21mm, 25mm and 30mm, and in diameters from 2.0mm to 4.5mm. This allows the clinician to use guided surgery to place a very broad range of implant sizes. For those cases where flapless surgery is indicated, there is a tissue punch provided for both the Standard and Wide formats. And for cases involving totally (or mostly) edentulous patients, the kit includes fix pins and fix pin drills in two lengths to anchor the surgical guide to the patient’s anatomy. The box, itself is intuitively organized for maximum utility, is suitable for autoclave sterilization and – when fully opened – tilts the instrument tray up 30° for easy accessibility.