Dean is an accomplished, dedicated and highly skilled Blogger/Content Creator with 25 years of experience performing enhancements and modifications to corporate messaging and blogs, assessing new standards, technologies and trends, and formulating plans for future enhancement to messaging strategies.

Moreover, Dean is skillful in writing in multiple styles/voices and contributing broadly to content generation as it relates to marketing programs and materials. Also, he is a results oriented leader with a track record of driving long-term success, and a demonstrated ability to generate a wide variety of content types and styles in his messaging.

Specialties: Blogging, Social Media Marketing, Web Content Development, Content Strategy and Newsletters

For those who missed Part I CLICK HERE

As Michael Foley shared in the first part, ceramic implants have been around for 30 years. Until recently the biggest knock on them was they were brittle and could break more easily than titanium implants. That’s not the case anymore, Foley noted in a recent email interview.

“The materials have evolved a lot. ZERAMEX® uses bio-friendly HIP ARZ Zirconia with ceramic. Our use of a different extraction and production process has helped our new ceramic implants to work more like titanium implants,” he wrote. One difference in the extraction process is the Zirconia ZERAMEX® uses is made from the oxide of Zirconium. Zirconium is a metal and in its oxidized state it has all the benefits of a metal (magnetic, heat transference, strength) but doesn’t degrade like Zirconium and titanium.

Secondly, ZERAMEX® presses, sinters and heats the Zirconia before pressing it into a rod. “In this state it becomes exceptionally strong,” Mike says. “Two thousand megapascal vs 1200 megapascal for titanium.”

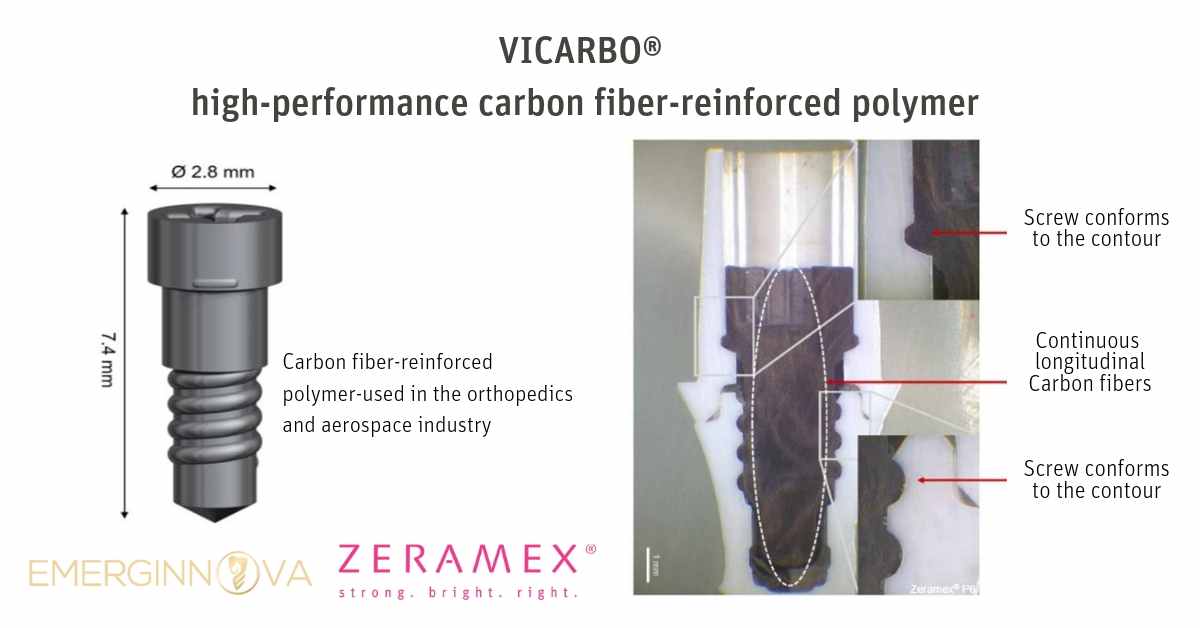

For those readers not fluent in pressure units and newtons (neither was I), suffice it to say 2,000 is stronger than 1,200 and that ceramic implants are much tougher than they used to be. We have had zero fractures or issues with this screw. It is really incredible,” he said.

Mike noted that the Vicarbo® screw is one of three pieces in a ZERAMEX® implant. “First is the implant that is surgically placed into the bone as an artificial tooth root – just like a titanium implant,” he noted. “Second is the abutment which is the crown and tooth portion, and third is the Vicarbo® screw which locks the root and tooth together.”

“The lateral forces pressing in between the implant and the abutment tightly seal the connection, preventing bacteria from entering the affected area and creating implantitis.”

“This is the sleeping dragon of dental implants,” Mike admitted. “We say that titanium implants have clinical success of 98 percent, but we don’t include the 20 percent of patients that get inflammation around the implant and have to return to the dentist for some sort of (gum) tissue treatment,” Mike said.

With his keen interest in bio-friendly dental solutions, this metal-free option is a huge factor for Mike and one of the primary reasons why he formed Emerginnova as a company focused on bio-friendly dental treatment.

CLICK HERE to read the FULL article

Contact

Want to know more about Zeramex?

Email us at [email protected] with your contact details and we will get in touch with you!

ZERAMEX BROCHURE

Click here to download the Zeramex sales brochure